Secador rotativo

Materiais aplicados:nEscória, cinza volante, serragem, caulim, lodo de carvão, gesso, calcário, argila, areia de rio, areia de quartzo, etc.- Poder:7.5-75kw

- Capacidade:1.9-76 TPH

O que é Secador Rotativo?

Secador rotativo

Estrutura razoável garante a eficiência de secagem

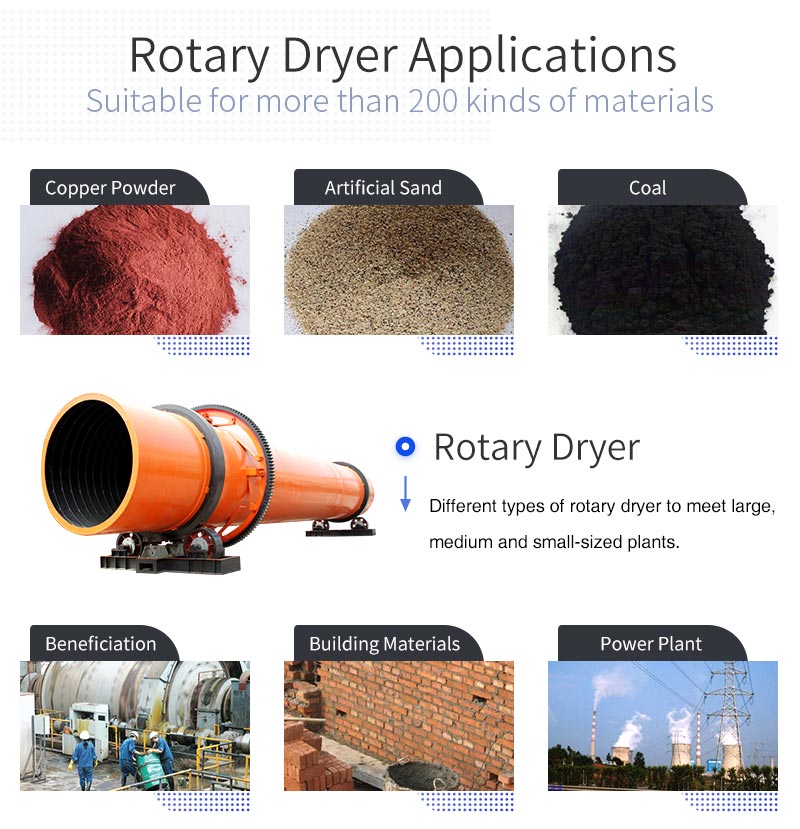

A aplicação do secador rotativo

Exemplos de aplicações de secadores rotativos

A classificação do secador de tambor rotativo

O princípio de funcionamento de um secador rotativo é baseado na gravidade e na troca de calor. Vamos pegar o secador rotativo de contracorrente como exemplo para explicar o processo:

Figura 1. Princípio de funcionamento do secador rotativo

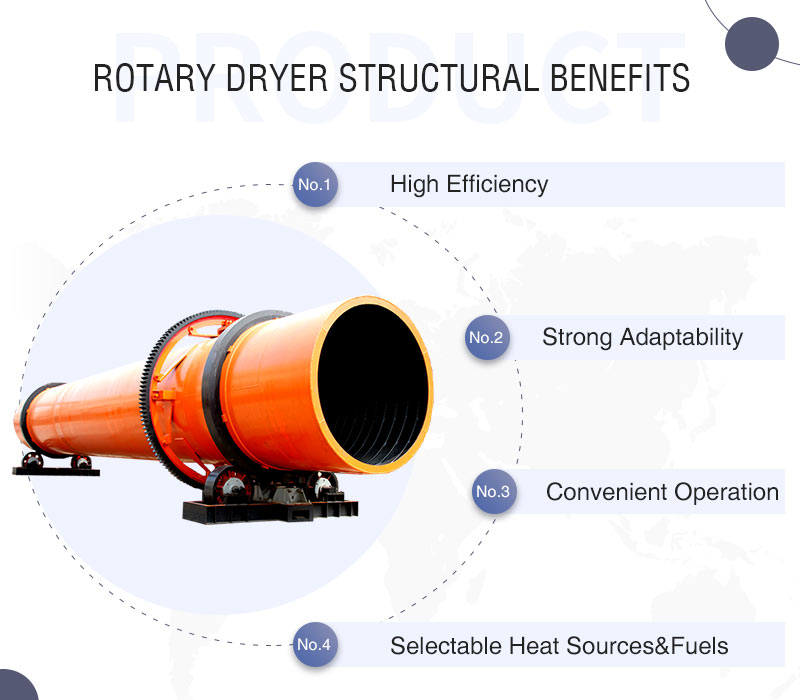

A Zoneding oferece secadores rotativos com várias vantagens que os tornam adequados para diferentes tipos de fábricas:

Benefícios do secador rotativo

Remessa de Secador Rotativo

Secador Rotativo Fabricante

serviço prestado ao cliente

Especificação geral

| Especificação/m (Diâmetro × Comprimento) | Cubagem de conchas (m³) | Capacidade (T / h) | Instalação Obliquidade (%) | Entrada mais alta Temperatura do ar (℃) | Motor principal (Kw) | Peso (T) |

| Φ1.2 × 8.0 | 9.0 | 1.9 2.4 ~ | 3 5 ~ | 700 800 ~ | 7.5 | 9 |

| Φ1.2 × 10 | 11.3 | 2.4 3.0 ~ | 3 5 ~ | 700 800 ~ | 7.5 | 11 |

| Φ1.5 × 12 | 21.2 | 4.5 5.7 ~ | 3 5 ~ | 700 800 ~ | 15 | 18.5 |

| Φ1.5 × 14 | 24.7 | 5.3 6.6 ~ | 3 5 ~ | 700 800 ~ | 15 | 19.7 |

| Φ1.5 × 15 | 26.5 | 5.7 7.1 ~ | 3 5 ~ | 700 800 ~ | 15 | 20.5 |

| Φ1.8 × 12 | 30.5 | 6.5 8.1 ~ | 3 5 ~ | 700 800 ~ | 18.5 | 21.5 |

| Φ1.8 × 14 | 35.6 | 7.6 9.5 ~ | 3 5 ~ | 700 800 ~ | 18.5 | 23 |

| Φ2.2 × 12 | 45.6 | 9.7 12.2 ~ | 3 5 ~ | 700 800 ~ | 22 | 33.5 |

| Φ2.2 × 14 | 53.2 | 11.4 14.2 ~ | 3 5 ~ | 700 800 ~ | 22 | 36 |

| Φ2.2 × 16 | 60.8 | 13.0 16.2 ~ | 3 5 ~ | 700 800 ~ | 22 | 38 |

| Φ2.4 × 14 | 63.3 | 13.5 16.9 ~ | 3 5 ~ | 700 800 ~ | 37 | 45 |

| Φ2.4 × 18 | 81.4 | 17.4 21.7 ~ | 3 5 ~ | 700 800 ~ | 37 | 49 |

| Φ2.4 × 20 | 90.4 | 19.3 24.1 ~ | 3 5 ~ | 700 800 ~ | 45 | 54 |

| Φ2.4 × 22 | 99.5 | 21.2 26.5 ~ | 3 5 ~ | 700 800 ~ | 45 | 58 |

| Φ2.6 × 24 | 127.4 | 27.2 34.0 ~ | 3 5 ~ | 700 800 ~ | 55 | 73 |

| Φ3.0 × 20 | 141.3 | 30.1 37.7 ~ | 3 5 ~ | 700 800 ~ | 75 | 85 |

| Φ3.0 × 25 | 176.6 | 37.7 47.1 ~ | 3 5 ~ | 700 800 ~ | 75 | 95 |

| Φ3.2 × 25 | 201 | 42.9 53.6 ~ | 3 5 ~ | 700 800 ~ | 90 | 110 |

| Φ3.6 × 28 | 285 | 60.8 76.0 ~ | 3 5 ~ | 700 800 ~ | 160 | 135 |

| concha diâmetro ×casca Comprimento Unid | Dentro da diâmetro de exterior concha (MM) | Dentro da diâmetro de interior concha (MM) | concha Comprimento (M) | concha cubagem (m³) | concha obliquidade | Elevação lâmina formulário | Maior entrada de ar temperatura (℃) | Dimensões (M) |

| Φ1.5 × 15m | 1500 | 500 | 15 | 20.27 | 3-5% | Formulário de elevação | 850 | 16.2 × 2.7 × 2.7 |

| Φ1.5 × 17m | 17 | 22.97 | 18.2 × 2.7 × 2.7 | |||||

| Φ1.5 × 19m | 19 | 25.68 | 20.0 × 2.9 × 2.9 | |||||

| Φ1.8 × 21m | 1800 | 650 | 21 | 35.91 | 3-5% | Formulário de elevação | 850 | 22.5 × 2.7 × 2.7 |

| Φ1.8 × 23m | 23 | 39.33 | 24.5 × 2.9 × 2.9 | |||||

| Φ1.8 × 25m | 25 | 42.75 | 26.5 × 2.9 × 2.9 | |||||

| Φ2.2 × 21m | 2200 | 800 | 21 | 58.10 | 3-5% | Formulário de elevação | 850 | - |

| Φ2.2 × 23m | 23 | 63.61 | ||||||

| Φ2.2 × 25m | 25 | 69.15 |

Produtos relacionados

Secador de tambor

Obtenha preço e suporte Whatsapp +8618637198006 Email: zd-machine@kssb.cn Obter preço Deixe uma mensagem Placas de elevação: As placas de elevação dentro do tambor desempenham um papel crucial. Eles levantam o pó ou partículas úmidas, permitindo…

Secador de Lodo

Obtenha preço e suporte Whatsapp +8618637198006 Email: zd-machine@kssb.cn Obter preço Deixe uma mensagem A máquina de secagem de lodo da Zoneding oferece diversas vantagens e benefícios estruturais. …

Secador de areia

Obtenha preço e suporte Whatsapp +8618637198006 E-mail: zd-machine@kssb.cn Obter preço Deixe um recado As vantagens de um secador rotativo de areia incluem: …

Secador de três tambores

Obtenha preço e suporte Whatsapp +8618637198006 E-mail: zd-machine@kssb.cn Obter preço Deixe uma mensagem,

Secador de Bentonita

Obtenha preço e suporte Whatsapp +8618637198006 Email: zd-machine@kssb.cn Obter preço Deixe uma mensagem Parâmetros técnicos do secador de calor indireto:,

Secador De Carvão

Obtenha preço e suporte Whatsapp +8618637198006 Email: zd-machine@kssb.cn Obter preço Deixe uma mensagem Parâmetros técnicos do secador de calor indireto:,

Secador de pasta

Obtenha preço e suporte Whatsapp +8618637198006 E-mail: zd-machine@kssb.cn Obter preço Deixe uma mensagem,

Secador de Escória

Obtenha preço e suporte Whatsapp +8618637198006 E-mail: zd-machine@kssb.cn Obter preço Deixe uma mensagem,

Secador de Pó de Minério

Obtenha preço e suporte Whatsapp +8618637198006 E-mail: zd-machine@kssb.cn Obter preço Deixe uma mensagem,

Secador de serragem

Obtenha preço e suporte Whatsapp +8618637198006 E-mail: zd-machine@kssb.cn Obter preço Deixe uma mensagem,

Carregando…

已经是到最后一篇内容了!

Máquina de Zoneamento

Máquina de Zoneamento